A recap on some of the Halo jobs I’ve been working on recently.

Harken Traveller Repair

Our wonderful Harken Windward Sheeting Traveller has started getting increasingly difficult to move. It came to a head during the Waikawa Regatta when it was totally stuck at one stage. I was advised by the professionals that I probably needed to replace the ball bearings. After doing my research I ordered 60 new Harken 5/16″ Torlon ball bearings from Fosters. What’s Torlon I hear you asking? “Torlon is a high performance amorphous (non-crystalline) engineering thermoplastic“!

To get the traveller off I needed to remove the track completely. I gave it a good clean before fitting the balls and added some Harken Onedrop ball bearing conditioner. With Peter’s help, I reinstalled the track.

Boy, it certainly made a difference. The traveller now glides from side to side effortlessly, even under full pressure during last week’s race.

USB Charger Outlet Upgrade

I upgraded one of the standard USB outlets to a new Dual Port USB-C & USB-A.

The small USB-C socket, as well as charging latest model phones, provides PD (Power Delivery) up to 12V 65W for powering tablets or laptops. Perfect for my Microsoft Surface laptop.

The USB-A socket, provides QC (Quick Charge) of latest model phones.

Annual Nanni Engine Service

Isaac from TS Marine did our yearly engine service. He did a great job as usual and I was especially pleased that he noticed and repaired a problem with a leaking seal in the sea water line between the impeller and the engine. Here’s his report:

Make an initial assessment of engine and what repairs are required

Locate and check batteries

Carry out cold start on engine

Check waterflow and charging

Visually inspect engine, belts, leaks, perished hose, leaking gland

Leave engine running at fast idle

Check engine again

Assess engine temperature

Shut engine down

Connect sucker to engine and start draining oil

Remove drive belts and assess drive and bearings

Re fit belt

Replace oil filter and refill engine oil

Start engine

Stop once there is pressure

Replace primary/secondary filters, strip clean where required

Shut off seacock, check operation

Clean water strainer

Remove and replace impeller

Check anodes

Check and set engine oil level

Replace gearbox oil

Adjust gland

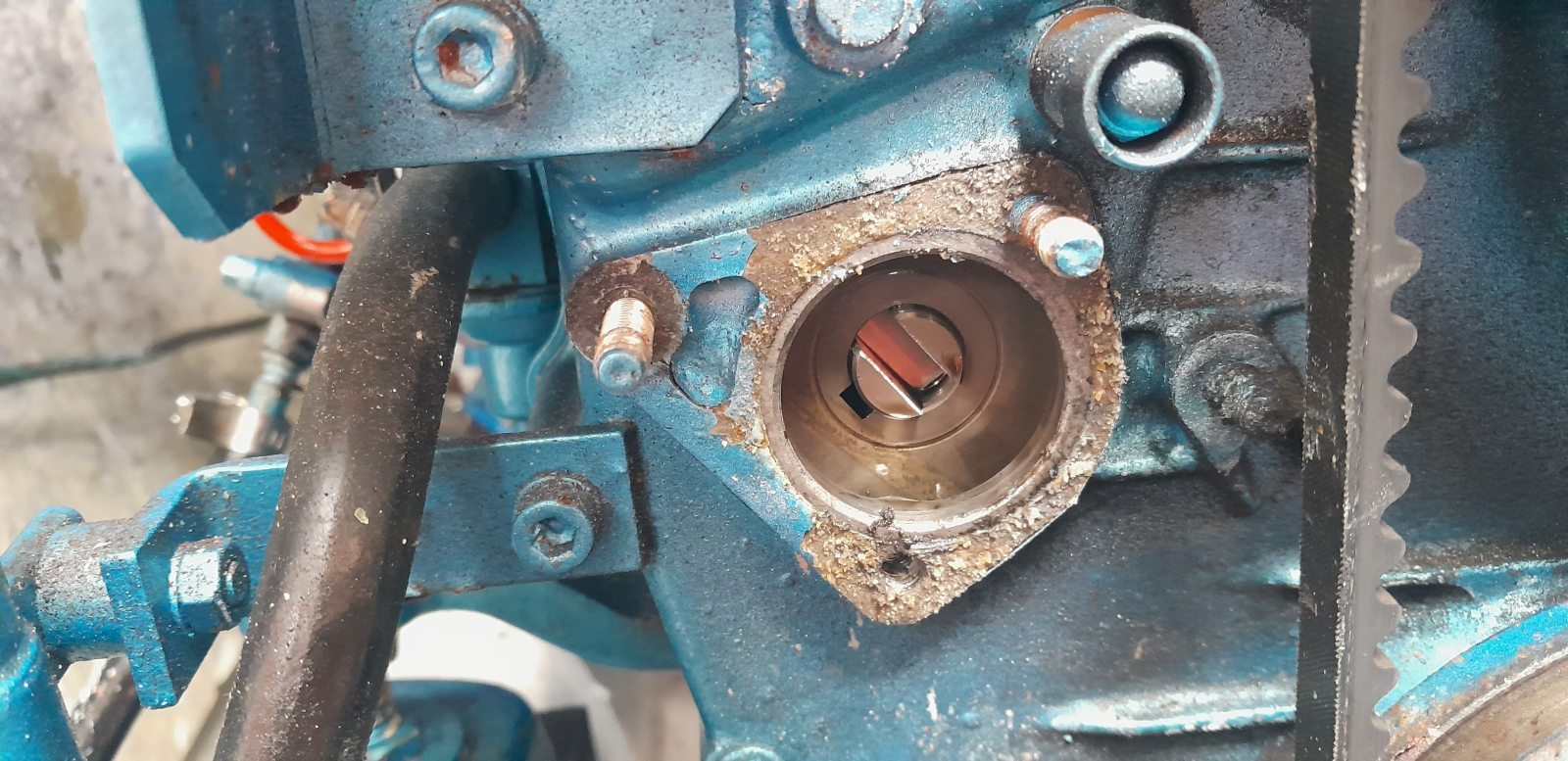

Remove Raw water pump and take to the workshop for bearing and seal replacement.

Engine hours: 683.7

Quick Slip – 18 October

Peter joined me to motor Halo round to the Evans Bay slipway and do a wash down of the hull. We also replaced replaced the prop shaft 1″ Zinc Anode.

We then went for a fun sail up the harbour. Picked up the club mooring south of Somes Island for a lunch break and then sailed back home.

Bilge Outlet Skin Fitting and Seacock Replacement

After the last outing I noticed that the bilge outlet sea cock was loose. A quick check from the outside revealed that the skin fitting was majorly cracked.

Picked up a replacement from Barton Marine. I was unable to remove the old seacock from the fitting without breaking it so I had to replace that also (using my birthday gift voucher – thanks Jenny and Jono!)

Interior Re-Paint

Some of the original interior paint was starting to peel off so decided to spruce it up and do the job properly. Mainly concentrating on the starboard side with a few touch ups in other places.

Resene Waterborne SureSeal – 2 coats

Resene Enamel Undercoat – 1 coat

Resene Lusta-Glo semi-gloss Enamel white paint – 2 coats

And for the plywood boards under the settee cushions:

Resene Lystacryl semi-gloss Waterborne – Double Spanish White – 2 coats

Quite time intensive but satisfying to have it all looking new and fresh.

Nasa Marine Wind Instrument Repair

We’ve had an ongoing issue with the NASA Marine Clipper Tactical Wind System wind angle indication. I have set the “Dead Ahead” various times while motoring ahead in no wind and it seems ok, plus or minus a couple of degrees. However when tacking close hauled into the wind we’re getting a consistent offset of 15-20 degrees from one tack to the other

After various discussions with NASA support they suggested we need to repair the MHU (Mast Head Unit). It’s out of warranty but rather than send the old one back they agreed to just send me a brand new replacement at their cost.

It’s now arrived and I just need to wait for a nice calm day to shinny up the mast and replace it.

P.D.

23 Nov 2023 – Installed the replacement mast head unit. Had to do three climbs up the mast (with Murray helping down below) as I was struggling to get the black mounting rod tightly secured to the mast mount bracket. Ended up putting a self tapping screw through the middle to keep it in position.

Murray and I then took advantage of the nice calm Wellington day to take Halo out into the harbour to calibrate the “dead ahead” to zero when motoring ahead.

Replace VHF External Speaker

24 Nov 2023. Replaced the VHF external speaker in the cockpit with a nice new white GME SPK45 Extension Speaker from Barton Marine. The old one had stopped working due to being all rusted up inside. We’ll see how long this new one lasts!